In the race to craft cleaner, fresher, and more expressive spirits, some distillers are turning down the heat—literally. Vacuum distillation, also known as cold distillation, is emerging as one of the most exciting techniques in modern beverage production. Unlike traditional distillation, which relies on heat to separate alcohol from a liquid mixture, vacuum distillation lowers the pressure inside the still, allowing the process to occur at far cooler temperatures.

The result? Spirits that retain delicate aromas and vibrant flavours that would otherwise be destroyed by heat. Once considered a laboratory novelty, this technique is now gaining traction among craft distilleries, high-end bars, and even large-scale producers of non-alcoholic beverages.

So, can lowering the temperature really raise the quality of your spirits? Let’s find out.

1. What Is Vacuum Distillation?

Traditional vs. Vacuum Distillation

Traditional distillation works by heating a liquid until the alcohol evaporates at around 78.37°C under normal atmospheric pressure. The alcohol vapour is then condensed and collected.

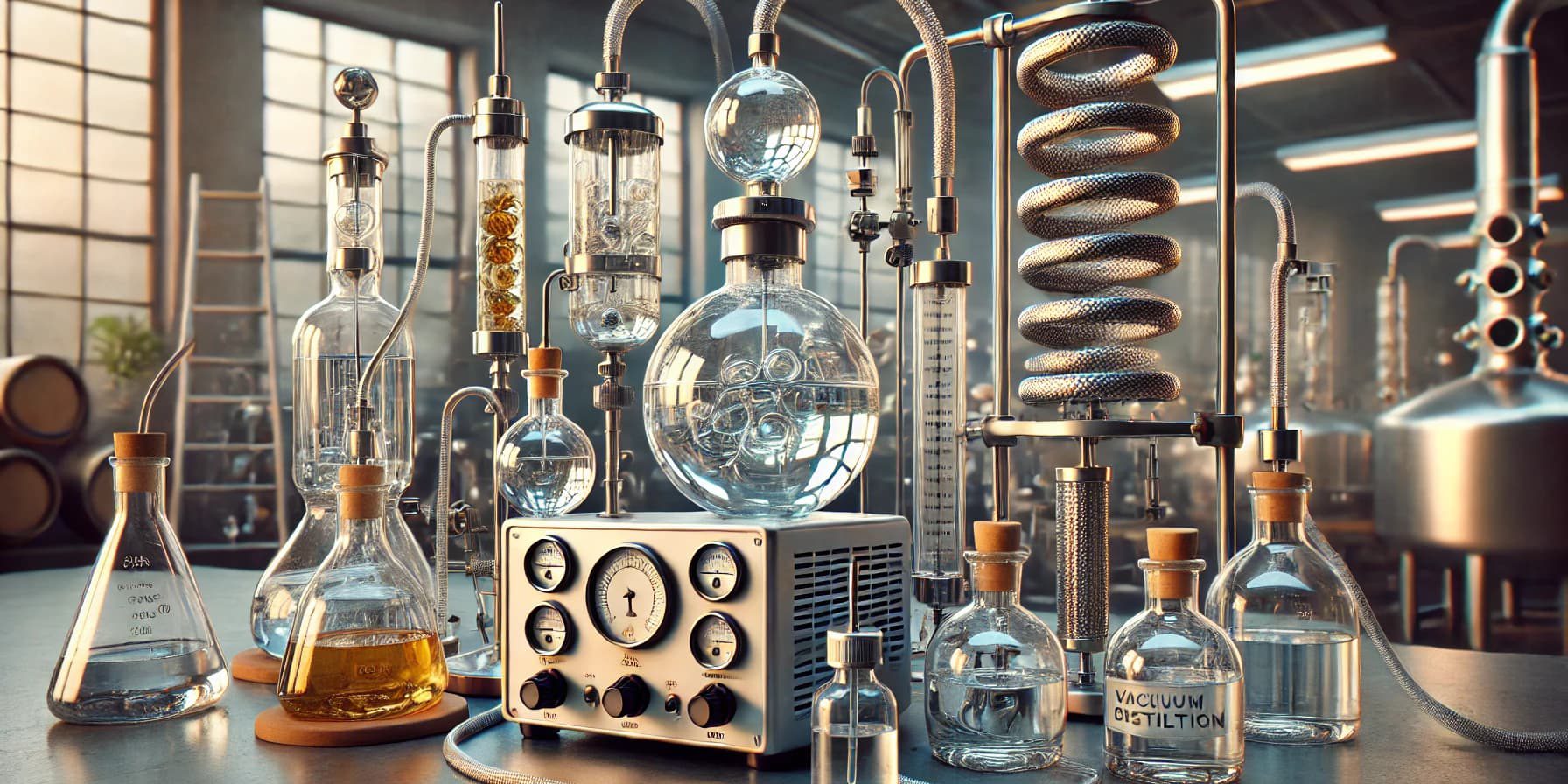

Vacuum distillation operates on the same principle, but by reducing the internal pressure of the still, it lowers the boiling point dramatically—often to between 20°C and 35°C. This allows alcohol and aromatic compounds to evaporate without being “cooked” by high heat, preserving their original sensory qualities.

Think of it like boiling water on a mountain: the lower the air pressure, the lower the boiling point. In distilling terms, this means gentler extraction and a truer expression of ingredients.

The Science Behind the Process

The reduced pressure environment protects volatile aromatic molecules that would normally degrade under heat. Common vacuum setups include rotary evaporators (rotovaps) or vacuum stills with precise pressure control. These systems allow distillers to fine-tune temperature and vacuum levels to extract exactly what they want — and nothing they don’t.

2. Why Distillers Are Turning Down the Heat

Preserving Delicate Flavours

The greatest appeal of vacuum distillation lies in flavour preservation. Many botanicals, fruits, and herbs contain heat-sensitive compounds that break down or caramelise at high temperatures. Distilling under vacuum locks in those vibrant, raw notes—think fresh apple and pear in brandy, or bright citrus and cucumber in gin.

Cleaner, Smoother Spirits

Lower distillation temperatures also mean fewer unwanted by-products such as fusel oils and methanol. The resulting spirit tends to be smoother, lighter, and cleaner, with less harsh “burn” on the palate—qualities increasingly favoured by today’s consumers.

Sustainability and Energy Efficiency

Operating at reduced temperatures naturally consumes less energy, both for heating and cooling. For producers seeking to reduce their carbon footprint or meet ESG goals, vacuum distillation offers a tangible sustainability advantage. Some distilleries are even exploring heat recovery systems or solar-assisted distillation, further enhancing energy efficiency.

Greater Control and Experimentation

Vacuum systems provide exceptional control over the distillation environment. Distillers can make fine adjustments to pressure, temperature, and duration, giving them freedom to experiment with unconventional ingredients—such as flowers, tea, or delicate botanicals that wouldn’t survive a traditional run. It’s an R&D playground that’s driving a new wave of creative spirits.

3. Beyond Alcohol: A Catalyst for the Non-Alcoholic Market

Meeting the Demand for No- and Low-Alcohol Products

Vacuum distillation isn’t just transforming spirits—it’s revolutionising non-alcoholic (NA) beverage production. With the rise of “sober-curious” consumers and wellness-driven drinking, demand for premium NA options is booming.

The technique allows producers to remove alcohol from wine, beer, or spirits without stripping flavour, maintaining the sensory profile of the original product. Companies like BevZero have built global businesses around large-scale vacuum systems designed specifically for dealcoholisation.

From Distillery to NA Innovation

For distilleries, vacuum distillation bridges the gap between traditional spirit-making and the fast-growing NA category. Brands such as Oxley Gin and Griffiths Brothers Distillery use cold distillation to produce exceptionally aromatic gins, while NA producers employ similar methods to create complex, alcohol-free alternatives. The technique offers producers a way to expand their portfolio into new markets without compromising craftsmanship.

4. Where It’s Being Used

Specialty Spirits and Craft Distilling

Vacuum distillation has roots in Japanese shochu production but has since found a new audience in the craft and premium sectors. Distillers such as Oxley Gin (UK), Empirical Spirits (Denmark), and Griffiths Brothers (UK) use the method to highlight specific botanicals and achieve unprecedented clarity of flavour.

High-End Bars and Culinary Innovation

At the smaller scale, rotary evaporators (rotovaps) are common tools in cocktail bars and experimental kitchens. Bartenders and chefs use them to create hydrosols and essences that capture fleeting flavours — for instance, the aroma of freshly cut grass or rose petals — that can’t be reproduced through heat. This crossover between mixology and distilling is inspiring a new appreciation for technique-driven flavour design.

5. Opportunities and Challenges

Opportunities

- Differentiation: Offer spirits with unmatched purity and flavour expression.

- Portfolio expansion: Introduce NA or hybrid products for new markets.

- Sustainability: Lower energy use aligns with environmental and regulatory goals.

- Premium storytelling: Craft narratives around innovation and craftsmanship that appeal to distributors and hospitality partners.

Challenges

- Capital investment: Vacuum systems and rotovaps can be costly and require maintenance.

- Technical complexity: Operators need training to manage pressure and temperature precisely.

- Scaling limits: While excellent for R&D and small batches, scaling up to industrial production requires specialised systems and expertise.

6. The Future of Cold Distillation

As the spirits industry evolves, vacuum distillation sits at the intersection of innovation, sustainability, and consumer preference. The technology is advancing rapidly, with automation, digital monitoring, and AI-assisted control becoming increasingly common.

We may soon see breweries using cold vacuum evaporation for hop extracts, or wineries concentrating flavour and aroma compounds in low-temperature environments. What began as a niche technique is fast becoming a mainstream production tool.

Conclusion

Vacuum distillation represents a quiet revolution in how we think about flavour, energy, and authenticity. By turning down the heat, distillers are discovering new ways to capture the essence of their ingredients—whether producing ultra-premium gins, smooth fruit brandies, or sophisticated non-alcoholic spirits.

Rather than replacing traditional methods, it complements them, expanding the creative and technical possibilities available to modern producers. In an industry where flavour integrity and sustainability define success, those who master the cold may just stay hottest in demand.